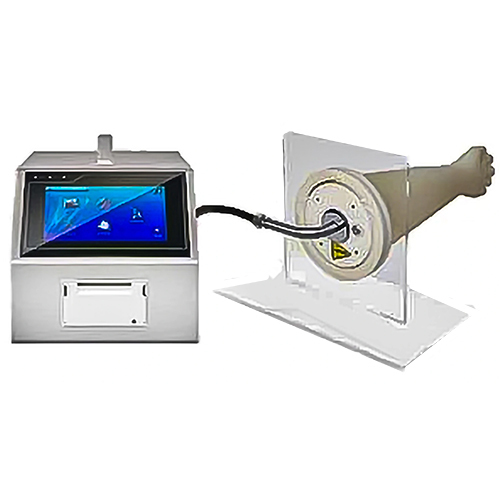

WGT-1200 Wireless Online Multi Units Glove Integrity Tester

WGT-1200 Wireless Online Multi Units Glove Integrity Tester Specification

- Response Time

- <1 second

- Operating Voltage

- 100-240V AC, 50/60Hz

- Features

- Wireless Operation, Multi-Port Testing, Data Logging, Audit Trail, Remote Monitoring, CFR21 Compliance

- Mounting Type

- Bench-top/Portable

- Port Size

- Standard Glove Port Adapter (options available)

- Humidity

- 10 90% RH (Non-condensing)

- Number of Specimens

- Up to 12 Gloves Simultaneously

- Hardness

- N/A (not applicable)

- Max Height

- 420 mm

- Temperature

- 10C 40C Operating Range

- Power Supply

- AC 220V, 50/60 Hz

- Gas Pressure

- 0.3 0.8 MPa (Compressed air)

- Interface Type

- Ethernet/USB/Wireless

- Test Range

- Room Pressure to 5000 Pa

- Application

- Sterility Glove Leak/Integrity Testing in Isolators/RABS, Pharma, Biotech

- Display Type

- 7-inch LCD Touchscreen

- Frequency

- Single/Multiple Test Cycles Selectable

- Automation Grade

- Automatic

- Equipment Type

- Wireless Online Glove Integrity Tester

- Specimen Size

- Typical Glove Port Diameter 190-210 mm

- Measuring Range

- 05000 Pa

- Resolution

- 1 Pa

- Accuracy

- 1% FS

- Usage

- Glove Integrity Verification

- Capacity

- Up to 12 Ports per Tester

- Machine Weight

- ~16 kg (main unit)

- Test Speed

- Standard/Customizable

- Test Width

- Single/Multiple Gloves Simultaneously

- Test Stroke

- Adjustable, up to 300 mm

- Control Mode

- Wireless Remote / Touchscreen Panel

- User Access

- Multi-level Password Security

- Data Output

- Export via USB/Ethernet/Cloud

- Test Method

- Pressure Decay/Leakage Detection

- Memory

- Store >1000 Test Records

- Software Compliance

- 21 CFR Part 11

- Language Support

- Multi-language User Interface

- Calibration

- Automatic/Manual Calibration Supported

- Alarm System

- Audio/Visual Alarms for Failed Tests

- Data Storage

- Internal Memory & External Backup

- Housing Material

- Stainless Steel 304

About WGT-1200 Wireless Online Multi Units Glove Integrity Tester

Instrument characteristics:

- It is connected to the PC wirelessly via WIFI, and the detection data can be transmitted wirelessly.

- Supporting powerful upper computer management software, which can manage multiple detection units at the same time.

- RFID chip technology, automatic identification of glove number, included in the test result.

- Meet the IP65 protection level, which is convenient for disinfection and cleaning of equipment.

- There are multiple preset scheme settings to meet the testing requirements of gloves of different specifications and materials.

- The pressure detection range can reach 3000Pa, covering all glove detection pressures.

- Built-in special sanitary air pump to inflate gloves/cuffs.

- Automatically monitor the pressure in the inflatable sealing ring and the glove during the test.

- The instrument uses a small amount of frequent air intake, and the air intake speed in the glove is uniform to avoid deformation of the glove.

- Color touch screen, user-friendly interface design, and can automatically select and match the testing program that best suits the current glove according to different test parameters, and display the date and time.

- Easy to move, easy to carry, fast connection.

- Historical records can be transmitted, stored, and inquired.

- According to customer needs, we can customize pallets of different sizes to achieve multiple pallet operations on one machine.

- Comply with FDA/GMP and other regulations and computer system verification requirements.

- The software complies with 21CFR part11 electronic records and electronic signature certification requirements.

Application field:

- Pharmaceutical industry: sterile inspection and microbial limit inspection of purified water, water for injection, sterile preparations (large infusion, small injection, powder, biological products, blood products, ophthalmic preparations, maintenance solutions, etc.).

- Medical equipment industry: sterility inspection and microbial limit inspection of purified water, water for injection, syringes, infusion sets, blood transfusion sets, intravenous catheters, etc.

- Food and beverage industry.

- Environmental protection industry, etc

Precision and Efficiency in Glove Testing

The WGT-1200 is designed for efficient, high-precision glove leak and integrity testing in isolators, RABS, and controlled environments. Capable of testing up to 12 gloves at once with standard or customizable speeds, it streamlines routine verification processes, significantly reducing labor and turnaround time, while ensuring sterility and compliance under regulatory standards.

Secure and Compliant Data Management

Ensuring data integrity is at the core of WGT-1200. With 21 CFR Part 11 compliance, all test results are securely logged and traceable through audit trails. User access is tightly regulated through multi-level password security, while data export and backup options-including USB, Ethernet, and cloud-facilitate robust documentation and analysis for audits and quality assurance.

Flexible and User-Friendly Operation

Operators benefit from a 7-inch LCD touchscreen, multi-language interface, and wireless remote control, making setup and test execution convenient and intuitive. The device supports both automatic and manual calibration, customizable test parameters, and a range of glove port sizes, adapting seamlessly to various industry requirements and user preferences.

FAQ's of WGT-1200 Wireless Online Multi Units Glove Integrity Tester:

Q: How does the WGT-1200 detect glove leaks during integrity tests?

A: The WGT-1200 utilizes a precise pressure decay/leakage detection method to assess glove integrity. During tests, it introduces a controlled pressure into each glove and monitors for any pressure loss, signaling a potential leak with high sensitivity and rapid response times.Q: What benefits does wireless operation provide for routine glove testing?

A: Wireless operation enables convenient remote management and monitoring of glove integrity tests, reducing manual intervention and increasing workflow efficiency. This is especially advantageous in environments requiring frequent tests, ensuring flexibility and operator safety.Q: When should the WGT-1200 be calibrated, and what are the options?

A: The WGT-1200 supports both automatic and manual calibration. Calibration frequency depends on institutional SOPs and usage intensity, but it is recommended before critical test batches or after major maintenance. Built-in prompts assist users in ensuring compliance and accuracy.Q: Where can test data from the WGT-1200 be stored and accessed?

A: Test data is securely stored within the device's internal memory for over 1000 test records. For backup or further analysis, results can be exported via USB, Ethernet, or cloud solutions, enabling convenient data sharing and long-term archiving in line with regulatory requirements.Q: What is the process for testing multiple gloves simultaneously with this equipment?

A: To test up to 12 gloves at once, users attach gloves to the designated ports and set parameters via the touchscreen or wireless controls. The device conducts individual leak tests on each port with adjustable stroke, speed, and pressure settings, then presents results on the display with audio/visual alerts for any failures.Q: Can the WGT-1200 accommodate different glove sizes and test requirements?

A: Yes, the WGT-1200 is designed for flexibility, supporting typical glove port diameters of 190-210 mm with adapter options available. Both standard and customizable test cycles ensure compatibility with a wide range of gloves and operational protocols.Q: What are the key advantages of using the WGT-1200 for pharmaceutical and biotech facilities?

A: The WGT-1200 delivers rapid, accurate glove integrity testing while meeting industry regulations for data integrity and electronic records. Its multi-port design, automation features, secure data handling, and robust construction make it an indispensable tool for sterility assurance and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Glove Integrity Tester Category

GT-2.0 Online Glove Integrity Tester

Resolution : 0.1 Pa

Measuring Range : 10 Pa 2000 Pa

Accuracy : 1 Pa

Power Supply : AC 220V 10%, 50Hz

Gas Pressure : 0.40.6 MPa

Test Width : Standard 200 mm

GT-2.0 Offline Glove Leakage Tester

Resolution : Visual (0.1 mm minimal observable)

Measuring Range : Visual detection of pinhole leakage

Accuracy : Highly sensitive, detects leakage 0.5mm

Power Supply : 220V AC, 50Hz

Gas Pressure : 0.10.3 MPa

Test Width : 240280 mm

WGT-1000 Wireless Online Single Glove Integrity Tester

Resolution : 0.01 ml/min

Measuring Range : 0.1~1000 ml/min

Accuracy : 0.1 ml/min

Power Supply : AC 220V, 50Hz

Gas Pressure : 0.4~0.6 MPa

Test Width : 250 mm

GT-3.0 Glove Integrity Tester Online

Resolution : 0.01 microliters/min

Measuring Range : 0.1 100 microliters/min

Accuracy : 0.2 microliters/min

Power Supply : 230 V AC, 50 Hz

Gas Pressure : 0.5 1.6 bar

Test Width : 300 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese