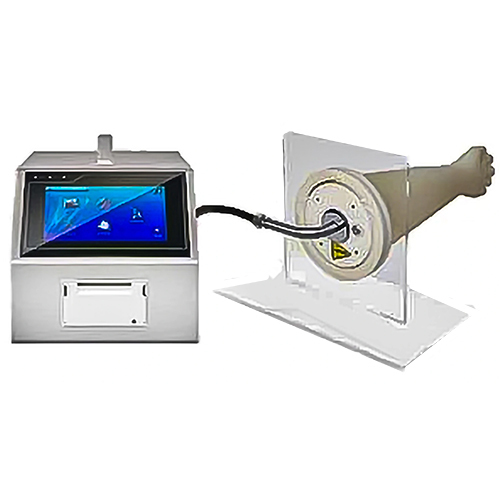

GT-2.0 Offline Glove Leakage Tester

GT-2.0 Offline Glove Leakage Tester Specification

- Accuracy

- Highly sensitive, detects leakage 0.5mm

- Display Type

- Digital display with indicator

- Frequency

- 50 Hz

- Automation Grade

- Semi-automatic

- Number of Specimens

- 1 piece per cycle

- Resolution

- Visual (0.1 mm minimal observable)

- Temperature

- 5-45C

- Operating Voltage

- 220V

- Port Size

- 8 mm

- Hardness

- Industrial standard steel body

- Power Supply

- 220V AC, 50Hz

- Interface Type

- Push button control interface

- Gas Pressure

- 0.1-0.3 MPa

- Test Range

- Complete Finger and Palm Coverage

- Specimen Size

- General glove size

- Humidity

- 20%-80% RH

- Equipment Type

- Offline Glove Leakage Tester

- Mounting Type

- Floor standing

- Response Time

- Immediate upon leakage detection

- Features

- User friendly, quick fixture adjustment, safe operation, robust construction

- Application

- Detecting micro-leakage in latex, nitrile, and PVC medical gloves

- Max Height

- 1100 mm

- Measuring Range

- Visual detection of pinhole leakage

- Usage

- Glove laboratory and production lines

- Capacity

- 1500 pcs/day

- Machine Weight

- 68 kg

- Test Speed

- 6-12 pieces/min (adjustable)

- Test Width

- 240-280 mm

- Test Stroke

- 0-420 mm

- Control Mode

- Automatic & Manual

- Lighting System

- Built-in LED for improved visual detection

- Air Consumption

- <3 L/min per test

- Testing Medium

- Compressed air

- Maintenance Requirement

- Low, easy cleaning

- Device Mobility

- Heavy-duty caster wheels

- Fixture Type

- Interchangeable glove fixture

- Safety Protection

- Over pressure auto cut off

- Noise Level

- <55 dB

- Programming

- Cycle timer adjustable

- Material of Construction

- Powder coated mild steel body

About GT-2.0 Offline Glove Leakage Tester

Features

- The instrument adopts a small amount of frequent air inlet mode, with uniform inlet velocity in gloves, to avoid gloves deformation.

- It is equipped with color touch screen and humanized interface design, according to different test parameters, for automatic selection and matching, which can be most adaptive to the current gloves test procedure, date and time display;

- The authority management and electronic signature design is in line with the 21 CFR part 11 for certification requirements of electronic records and electronic signature;

- It is convenient to move, easy to carry and quick to connect;

- Historical records can be used for print, storage and query

Efficient and Accurate Glove Testing

Designed for the fast-paced demands of glove production and laboratories, the GT-2.0 Offline Glove Leakage Tester delivers reliable, accurate leak detection for up to 1500 gloves per day. With immediate response time, high sensitivity, and the ability to visually detect pinholes as small as 0.5 mm, this tester enhances quality assurance processes with minimal operator effort.

Flexible and User-Friendly Operation

Operators benefit from an intuitive push-button interface, adjustable cycle timing, and quick fixture changes to accommodate various glove sizes. The automatic and manual control modes offer flexibility, while the built-in LED lighting ensures clear visibility, reducing the risk of inspection errors during testing.

Robust Construction for Demanding Environments

Crafted from powder-coated mild steel with industrial-standard hardness, the GT-2.0 is built to withstand heavy usage. Its floor-standing design, heavy-duty caster wheels, and easy-clean maintenance make it suitable for continuous operation in laboratories and glove manufacturing facilities across India.

FAQ's of GT-2.0 Offline Glove Leakage Tester:

Q: How does the GT-2.0 Offline Glove Leakage Tester detect leakage in gloves?

A: The tester uses compressed air to inflate gloves and visually detect any pinhole leakage using its highly sensitive system and built-in LED lighting, allowing for immediate identification of leaks as small as 0.5 mm.Q: What types of gloves can be tested with this device?

A: It is designed to test latex, nitrile, and PVC medical gloves of general sizes, providing complete finger and palm coverage for comprehensive leak detection.Q: When should regular maintenance be performed on the GT-2.0 tester?

A: The GT-2.0 is engineered for low maintenance. Routine cleaning after daily operations suffices, thanks to its easy-clean design. Check fixtures and connections periodically for optimal performance.Q: Where is this glove leakage tester commonly used?

A: This equipment is widely used in glove laboratories, production lines, and quality assurance departments of medical glove manufacturers and suppliers, particularly in India.Q: What is the process for using the GT-2.0 to test gloves?

A: Place a glove on the interchangeable fixture, set the cycle timer, and select either the automatic or manual mode. The device fills the glove with compressed air, and any leaks are visually detected with the help of the integrated LED lighting. The process takes only a few seconds per glove.Q: What are the benefits of using the GT-2.0 Offline Glove Leakage Tester?

A: Benefits include high testing capacity (up to 1500 pcs/day), rapid and accurate detection, simple operation, robust safety features, low noise, and suitability for a wide range of glove types and production environments.Q: How user-friendly is the operation of the GT-2.0 tester?

A: It features a push-button control interface, adjustable programming, and quick fixture adjustments, making it easy for operators without advanced technical skills to use effectively.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Glove Integrity Tester Category

GT-2.0 Online Glove Integrity Tester

Mounting Type : Portable/desktop

Response Time : 3 sec

Application : For glove leak/integrity testing in isolators/RABS

Features : Automatic report, data storage, pass/fail display

Equipment Type : Online Glove Integrity Tester

Max Height : 310 mm

WGT-1000 Wireless Online Single Glove Integrity Tester

Mounting Type : Clamp or flange mounting

Response Time : 3 seconds

Application : Glove leak/air tightness testing in isolators, RABS, and gloveboxes

Features : Wireless operation, automatic data logging, rapid leak detection, easy mounting and removal

Equipment Type : Online Glove Integrity Tester

Max Height : 400 mm (including mounting)

WGT-1200 Wireless Online Multi Units Glove Integrity Tester

Mounting Type : Benchtop/Portable

Response Time : <1 second

Application : Sterility Glove Leak/Integrity Testing in Isolators/RABS, Pharma, Biotech

Features : Wireless Operation, MultiPort Testing, Data Logging, Audit Trail, Remote Monitoring, CFR21 Compliance

Equipment Type : Wireless Online Glove Integrity Tester

Max Height : 420 mm

GT-3.0 Glove Integrity Tester Online

Mounting Type : Wall/Panel Mount

Response Time : < 3 seconds

Application : Leak Testing of RABS/Isolator Gloves

Features : Automatic Leak Detection, Data Logging, Alarms

Equipment Type : Glove Integrity Tester

Max Height : 450 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese