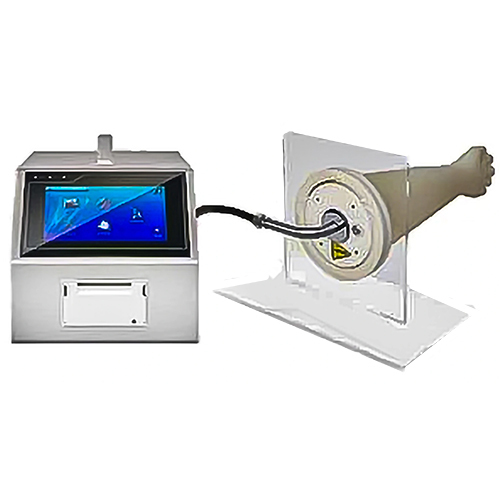

GT-3.0 Glove Integrity Tester Online

GT-3.0 Glove Integrity Tester Online Specification

- Max Height

- 450 mm

- Response Time

- < 3 seconds

- Test Range

- 1.0 micron 100 micron

- Port Size

- Standard Glove Port: 8 / 10

- Specimen Size

- Standard Glove Sizes

- Features

- Automatic Leak Detection, Data Logging, Alarms

- Equipment Type

- Glove Integrity Tester

- Interface Type

- RS232 / USB

- Automation Grade

- Fully Automatic

- Gas Pressure

- 0.5 - 1.6 bar

- Number of Specimens

- Up to 6 gloves per cycle

- Application

- Leak Testing of RABS/Isolator Gloves

- Resolution

- 0.01 microliters/min

- Operating Voltage

- 230 VAC

- Humidity

- Up to 80% RH

- Display Type

- LED Digital

- Power Supply

- 230 V AC, 50 Hz

- Temperature

- 10C 40C

- Accuracy

- 0.2 microliters/min

- Mounting Type

- Wall/Panel Mount

- Frequency

- 50 Hz

- Measuring Range

- 0.1 100 microliters/min

- Usage

- Pharmaceutical, Biotech

- Capacity

- Multiple Glove Ports

- Machine Weight

- Approx. 18 kg

- Test Speed

- 1 Cycle/Minute

- Test Width

- 300 mm

- Test Stroke

- Up to 150 mm

- Control Mode

- Online Digital Control

- Language Support

- Multi-language user interface

- Data Storage

- Internal Memory for up to 1000 test results

- Alarm System

- Visual and Acoustic Alarms for Leak Detection

- Test Modes

- Standard, Custom, Validation, and Data Logging

- Data Output

- PDF/CSV report via USB/Ethernet

- Status Indication

- LED Indication and Home Screen Status

- Accessories

- Supplied with calibration kit & test adapters

- Compliance Standards

- ISO 14644-7, cGMP, PIC/S

- Housing

- Stainless steel 316L, IP54 Protection Rated

- Maintenance

- Tool-less port adapter system for easy maintenance

- Operation

- Hands-free, user-friendly operation with remote start

- Self Diagnostics

- Routine system health check and error notification

About GT-3.0 Glove Integrity Tester Online

Product Features

- The instrument adopts a small amount of frequent air inlet mode, with uniform inlet velocity in gloves, to avoid gloves deformation.

- The authority management and electronic signature design is in line with the 21 CFR part 11 for certification requirements of electronic records and electronic Signature.

- Historical records can be used for print, storage, and query.

- It is equipped with a color touch screen and humanized interface design, according to different test parameters, for automatic selection and matching, which can be most adaptive to the current gloves test procedure, date, and time display.

- It is convenient to move, easy to carry, and quick to connect.

Application Area

- Pharmaceutical industry

- Medical device industry

- Food and beverage industry

- Environmental protection industry

Technical Parameter

- Working power supply: AC 220V 50Hz, 120W with battery

- Rated power: 2-8min

- Pressure range: 500-5000Pa

- Response value: 50Pa

- Noise: 50dB(A)

- Working mode: Continuous work

- External gas source: Compressed air, nitrogen, inert gas

- Sealing pressure: 0.8Mpa

- Other function: Audit trail, data export by USB (customization)

- Historical record: 10000 groups

- Print Function: Built-in Printer

- Dimensions: 400260270*250mm

- Weight: 10KG

- On-line gloves tray: Can supply one free, if need more customization

- Battery: Li-ion battery

- Pump: Oil, water-free, can customize-built in pump

Comprehensive Leak Detection

The GT-3.0 uses highly sensitive visual and acoustic alarms to instantly detect glove leaks, safeguarding critical operations in pharmaceutical and biotech facilities. Its automatic and user-friendly detection system enhances personnel and product safety, providing confidence in contamination control.

Designed for Compliance and Efficiency

Engineered specifically for strict regulatory environments, the GT-3.0 complies with ISO 14644-7, cGMP, and PIC/S standards. Its digital controls, quick cycle times, and multi-language interface ensure seamless workflow integration and adaptability in global applications.

Streamlined Data Management

With internal storage for up to 1000 test records and quick data output to PDF or CSV via USB/Ethernet, the GT-3.0 simplifies audit trails and regulatory submissions. Its automated logging, self-diagnostics, and clear status indicators reduce manual workload and potential for error.

FAQs of GT-3.0 Glove Integrity Tester Online:

Q: How does the GT-3.0 Glove Integrity Tester detect leaks during testing?

A: The GT-3.0 identifies leaks using advanced automatic detection technology, triggering immediate visual and acoustic alarms when a breach is found. The digital system measures and records leakage rates with high accuracy, ensuring reliable results and reducing the risk of contamination.Q: What compliance and safety standards does the GT-3.0 meet?

A: This tester fully complies with international standards including ISO 14644-7, cGMP, and PIC/S, making it suitable for critical applications in pharmaceutical and biotech industries. Its robust 316L stainless steel build, IP54 protection, and advanced safety features help to maintain regulatory adherence.Q: When should glove leak tests be performed using the GT-3.0?

A: Glove integrity testing should be conducted during initial installation, routine maintenance, after glove replacement, and periodically as dictated by regulatory requirements or internal protocols to ensure ongoing protection against potential breaches.Q: Where can the GT-3.0 be installed or mounted for operation?

A: The GT-3.0 is designed for wall or panel mounting, making it versatile for installation near RABS and isolators within cleanroom or controlled environments common in pharmaceutical and biotech facilities.Q: What is the process for conducting a test, and how user-friendly is the operation?

A: Testing begins with a remote, hands-free start. The operator selects a test mode (Standard, Custom, or Validation), then the system automatically handles the integrity check, alarm signaling, data logging, and reporting. The multi-language LED home screen and tool-less adapter system ensure ease of use and maintenance.Q: What benefits does data logging and internal memory provide?

A: The built-in data storage for up to 1000 test results allows users to efficiently manage records, generate PDF/CSV reports, and meet audit or compliance needs without paper-based logs. This feature also supports quality control and process traceability.Q: Who should use the GT-3.0 Glove Integrity Tester?

A: The tester is ideal for pharmaceutical, biotech, and other regulated industries requiring routine glove leak testing for RABS and isolator systems. It is suitable for operators, quality assurance personnel, and facility managers focused on maintaining high safety and compliance standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Glove Integrity Tester Category

WGT-1200 Wireless Online Multi Units Glove Integrity Tester

Hardness : N/A (not applicable)

Measuring Range : 05000 Pa

Machine Weight : ~16 kg (main unit)

Usage : Glove Integrity Verification

Control Mode : Wireless Remote / Touchscreen Panel

Test Stroke : Adjustable, up to 300 mm

WGT-1000 Wireless Online Single Glove Integrity Tester

Hardness : N/A (not applicable)

Measuring Range : 0.1~1000 ml/min

Machine Weight : 15 kg

Usage : Online glove integrity/leak testing

Control Mode : Wireless remote control

Test Stroke : Standard 350 mm

GT-2.0 Offline Glove Leakage Tester

Hardness : Industrial standard steel body

Measuring Range : Visual detection of pinhole leakage

Machine Weight : 68 kg

Usage : Glove laboratory and production lines

Control Mode : Automatic & Manual

Test Stroke : 0420 mm

GT-2.0 Online Glove Integrity Tester

Hardness : Industrial grade

Measuring Range : 10 Pa 2000 Pa

Machine Weight : Approx. 15 kg

Usage : Pharmaceutical isolator glove leak detection

Control Mode : Touchscreen PLC

Test Stroke : Adjustable 10250 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese