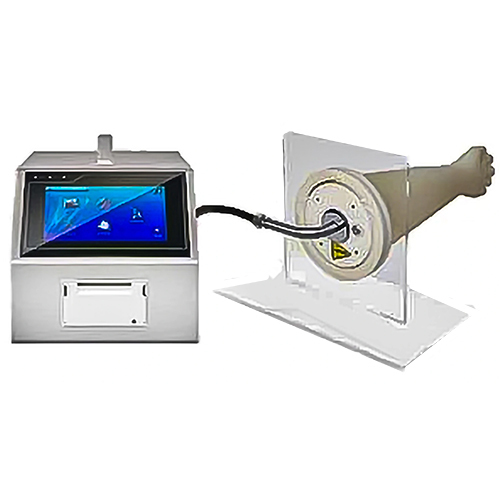

GT-2.0 Online Glove Integrity Tester

GT-2.0 Online Glove Integrity Tester Specification

- Automation Grade

- Automatic

- Display Type

- 7 TFT touchscreen

- Equipment Type

- Online Glove Integrity Tester

- Accuracy

- 1 Pa

- Response Time

- 3 sec

- Max Height

- 310 mm

- Temperature

- 10-40C

- Mounting Type

- Portable/desktop

- Number of Specimens

- Up to 1 glove per test cycle

- Specimen Size

- Glove port diameter 190 mm

- Port Size

- Standard 6 mm

- Test Range

- 10 Pa to 2000 Pa

- Interface Type

- USB

- Frequency

- 50/60 Hz

- Humidity

- 20%-90% RH

- Resolution

- 0.1 Pa

- Application

- For glove leak/integrity testing in isolators/RABS

- Features

- Automatic report, data storage, pass/fail display

- Gas Pressure

- 0.4-0.6 MPa

- Hardness

- Industrial grade

- Measuring Range

- 10 Pa - 2000 Pa

- Operating Voltage

- 220V

- Power Supply

- AC 220V 10%, 50Hz

- Usage

- Pharmaceutical isolator glove leak detection

- Capacity

- Single glove at a time

- Machine Weight

- Approx. 15 kg

- Test Speed

- 1-60 rpm adjustable

- Test Width

- Standard 200 mm

- Test Stroke

- Adjustable 10-250 mm

- Control Mode

- Touchscreen PLC

- Battery Backup

- Optional, up to 2 hours

- Software Update

- USB firmware upgradeable

- Test Media

- Compressed dry air

- Enclosure Protection

- IP54 rated

- Printer Interface

- Yes, built-in thermal printer

- Calibration

- Auto/Manual with calibration certificate

- Support Languages

- English/Chinese

- Data Storage Capacity

- Up to 1000 test records

- Implementation Standards

- Conforms to ISO 14644-7

- Alarm System

- Automatic audible/visible alarm

- Ambient Noise Level

- < 70 dB

- Dimensions (LxWxH)

- 420 x 280 x 310 mm

About GT-2.0 Online Glove Integrity Tester

- The instrument adopts a small amount of frequent air inlet mode, with uniform inlet velocity in gloves, to avoid gloves deformation.

- It is equipped with color touch screen and humanized interface design, according to different test parameters, for automatic selection and matching, which can be most adaptive to the current gloves test procedure, date and time display;

- The authority management and electronic signature design is in line with the 21 CFR part 11 for certification requirements of electronic records and electronic signature;

- It is convenient to move, easy to carry and quick to connect;

- Historical records can be used for print, storage and query

Precision and Compliance for Critical Environments

Engineered to meet ISO 14644-7 standards, the GT-2.0 ensures the highest level of glove integrity testing required in pharmaceutical isolators and RABS. With an accuracy of 1 Pa and a measuring range from 10 Pa to 2000 Pa, the device delivers fast, reliable results that help maintain contamination control in sensitive production environments.

User-Friendly Operation and Intelligent Control

Featuring a large, 7-inch TFT touchscreen PLC, the GT-2.0 offers streamlined operation with adjustable test speed (1-60 rpm) and stroke. The intuitive interface supports English and Chinese, making it accessible for diverse users. The built-in automated report and pass/fail display adds clarity and efficiency to glove integrity analysis.

Robust Design and Versatile Connectivity

With IP54 enclosure protection and industrial-grade build, the tester operates reliably in challenging conditions. It supports USB firmware upgrades and includes a built-in thermal printer for instant data output. Optional battery backup ensures testing continuity during power interruptions. Its compact, portable design allows easy setup on any desktop.

FAQ's of GT-2.0 Online Glove Integrity Tester:

Q: How does the GT-2.0 Online Glove Integrity Tester identify glove leaks?

A: The GT-2.0 uses compressed dry air to inspect gloves, monitoring pressure changes with high accuracy sensors. Any detected pressure loss indicates a potential leak, which prompts immediate audible and visual alarms, ensuring faults are detected quickly.Q: What types of environments are suitable for using the GT-2.0 tester?

A: This tester is ideal for pharmaceutical isolators and Restricted Access Barrier Systems (RABS) in cleanroom settings, as it meets ISO 14644-7 standards and has an IP54-rated enclosure for dust and water resistance.Q: When should glove integrity tests be performed using this device?

A: Routine glove integrity tests should be conducted before each use of isolators or RABS to ensure contamination control, as well as after glove replacements or user interventions as part of standard operating procedures.Q: Where is the data from the glove tests stored, and how can it be retrieved?

A: The GT-2.0 can store up to 1000 test records internally. Results and reports can be immediately printed using the built-in thermal printer or transferred via its USB interface for digital record-keeping and further analysis.Q: What is the process for calibrating the GT-2.0 tester?

A: Calibration can be set to either automatic or manual mode, and every unit comes with a calibration certificate. This ensures ongoing accuracy and compliance with industry quality standards.Q: How do users benefit from the device's alarm and report features?

A: The automatic audible and visible alarm system immediately notifies users of test anomalies, reducing response time. Coupled with automated pass/fail displays and instant report printing, users enjoy enhanced documentation and prompt decision-making.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Glove Integrity Tester Category

GT-2.0 Offline Glove Leakage Tester

Mounting Type : Floor standing

Number of Specimens : 1 piece per cycle

Capacity : 1500 pcs/day

Response Time : Immediate upon leakage detection

Max Height : 1100 mm

Temperature : 545C

WGT-1200 Wireless Online Multi Units Glove Integrity Tester

Mounting Type : Benchtop/Portable

Number of Specimens : Up to 12 Gloves Simultaneously

Capacity : Up to 12 Ports per Tester

Response Time : <1 second

Max Height : 420 mm

Temperature : 10C 40C Operating Range

WGT-1000 Wireless Online Single Glove Integrity Tester

Mounting Type : Clamp or flange mounting

Number of Specimens : 1 glove

Capacity : Single glove station

Response Time : 3 seconds

Max Height : 400 mm (including mounting)

Temperature : 10C~40C

GT-3.0 Glove Integrity Tester Online

Mounting Type : Wall/Panel Mount

Number of Specimens : Up to 6 gloves per cycle

Capacity : Multiple Glove Ports

Response Time : < 3 seconds

Max Height : 450 mm

Temperature : 10C 40C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese