7201 AeroTrak-Plus Remote Particle Counter

7201 AeroTrak-Plus Remote Particle Counter Specification

- Frequency

- 50/60 Hz

- Interface Type

- Ethernet, Modbus TCP/IP, RS-485

- Mounting Type

- Wall & Panel Mount

- Humidity

- 0 to 95% RH (non-condensing)

- Operating Voltage

- 24 VDC

- Features

- Built-in purge, Stainless steel enclosure, Data logging, ISO 21501-4 compliant

- Measuring Range

- 0.2 to 10.0 m

- Application

- Cleanroom Monitoring, Pharmaceutical, Semiconductor Manufacturing

- Accuracy

- Compliant with ISO 21501-4

- Display Type

- LED Status Indicators

- Resolution

- 0.1 m increments

- Automation Grade

- Automatic

- Temperature

- 0C to 40C (Operating), -10C to 50C (Storage)

- Gas Pressure

- Operating: 80-110 kPa

- Power Supply

- 24 VDC

- Response Time

- Real-time (1 second updates)

- Equipment Type

- Remote Particle Counter

- Test Range

- 0.2 to 10.0 m particle size

- Port Size

- 1/4 Swagelok

- Usage

- Continuous Particle Counting

- Capacity

- Continuous Monitoring

- Machine Weight

- 2.1 kg

- Test Speed

- 0.1 to 1.0 CFM (cubic feet per minute)

- Control Mode

- Remote Operation

- Communication Ports

- Ethernet, RS-485, USB Service

- Flow Rate

- 1.0 CFM (28.3 L/min)

- Size Channels

- Up to 6 user-selectable channels

- Ingress Protection

- IP65 Rated Enclosure

- Counting Efficiency

- 50% at 0.2 m; 100% for particles >0.3 m

- Light Source

- Long-life Laser Diode

- Compliance

- ISO 14644, EU GMP, 21 CFR Part 11

- Enclosure Material

- Stainless Steel

- Remote Operation Range

- Up to 100 m (Ethernet)

- Alarm Outputs

- 2 Programmable Relays

About 7201 AeroTrak-Plus Remote Particle Counter

Features and Benefits

- Easy installation and reliable operation with reduced costs

- Reliable laser technology backed by the industrys longest warranty (five years)

- Secure, long-term collection and storage of critical manufacturing data

- Reduce installation costs and complexitywireless enabled with minimal infrastructure

- Identifies industrys widest range of particle sizes by way of available model options

- Simplifies integration with Ethernet or DC power

- Reliable operation with heavy industrial electrical immunity compliance

- Early-warning of adverse environmental trends with per second sampling

- Predictive instrument maintenance alerts

- ISO 14644-14 suitability for use classified

- Sealed inlet prevents accidental ingress of cleaning solutions

- Rapid setup and unit configuration using standard USB-C cable

- Easy integration into TSI FMS Software with sensor auto discovery

- Easy Integration into third party systems with 4-20 mA analog data output model options

- Model 7510 only

- Enables 21 CFR Part 11 data collection with FMS Software

- Meets EU and US FDA Aseptic Processing Guidelines with 1 CFM (28.3 L/min) flow rate, 0.5 m and 5 m size channel size options

- Vaporized hydrogen peroxide (VHP) resistant model option

Advanced Continuous Monitoring

The AeroTrak-Plus 7201 excels in uninterrupted particle detection, providing real-time updates every second. Its robust performance makes it ideal for facilities where maintaining ultra-clean air quality is essential, empowering operators with up-to-the-second data for immediate decision-making.

Smart Integration and Automation

Offering versatile remote operation via Ethernet and Modbus TCP/IP, this particle counter simplifies integration into automated facility systems. Built-in data logging, programmable relay alarms, and compatibility with industry standards streamline monitoring processes and regulatory compliance.

Durable, Hygienic Design

Constructed with a stainless steel IP65-rated enclosure, the 7201 AeroTrak-Plus boasts exceptional durability and ingress protection. It withstands rigorous cleaning protocols and harsh industrial environments, ensuring long-term operation and hygiene in mission-critical settings.

FAQ's of 7201 AeroTrak-Plus Remote Particle Counter:

Q: How does the 7201 AeroTrak-Plus Remote Particle Counter operate in cleanroom environments?

A: This device continuously monitors airborne particles with real-time, one-second updates. It detects particles from 0.2 to 10 m in size and can be remotely controlled over Ethernet up to 100 meters, ensuring accurate and responsive cleanroom monitoring.Q: What are the main benefits of using a long-life laser diode in this particle counter?

A: The long-life laser diode ensures consistent, accurate particle detection over extended periods, reducing maintenance needs and minimizing downtime. It achieves 50% counting efficiency at 0.2 m and 100% for particles larger than 0.3 m, delivering reliable results.Q: Where can the AeroTrak-Plus 7201 be installed for optimal performance?

A: With its wall- and panel-mounting options and IP65-rated stainless steel enclosure, the device can be installed in various challenging environments, including pharmaceutical cleanrooms and semiconductor manufacturing areas, where durability and hygiene are critical.Q: What process does the AeroTrak-Plus use for data communication and integration?

A: It supports Ethernet, RS-485, and USB service for fast and secure data transfer. Advanced interfaces such as Modbus TCP/IP allow easy integration with facility management and automation systems, ensuring seamless operation and data logging.Q: When should the programmable alarm relays be utilized?

A: The two user-programmable alarm relays can be set to activate when particle counts exceed set thresholds. This immediate feedback lets operators respond swiftly to potential contamination events, maintaining compliance and product safety.Q: How is the AeroTrak-Plus beneficial for pharmaceutical and semiconductor applications?

A: Its compliance with ISO 14644, EU GMP, and 21 CFR Part 11, coupled with high measurement accuracy and reliable continuous monitoring, helps meet stringent industry standards, safeguarding production quality and regulatory adherence in critical manufacturing sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Particle Counter Category

7510 AeroTrak-Plus Remote Particle Counter

Accuracy : Better than 10% at 0.5 m and above

Usage : Particle counting in controlled environments

Control Mode : Remote / External via Modbus, BACnet, or Ethernet/IP

Power Supply : PoE (Power over Ethernet) or 24 VDC

Mounting Type : Wall or panel mount

Interface Type : Ethernet (TCP/IP), Modbus TCP, BACnet IP, Ethernet/IP

7310 AeroTrak-Plus Remote Particle Counter

Accuracy : Meets ISO 215014 and JIS B9921

Usage : Continuous particle monitoring

Control Mode : RS485 / Modbus

Power Supply : 24 VDC, 1.25 A

Mounting Type : Wallmounted or panelmounted

Interface Type : RS485, Ethernet, Modbus TCP/IP

6501 AeroTrak-Plus Remote Particle Counter With Integrated Pump

Accuracy : Exceeds ISO 215014 and JIS B9921 standards

Usage : Continuous particle monitoring in critical environments

Control Mode : Remote Control via Software/Network

Power Supply : 24 VDC, external (10%)

Mounting Type : Panel or wall mountable

Interface Type : Ethernet (TCP/IP), Modbus TCP, Web Interface

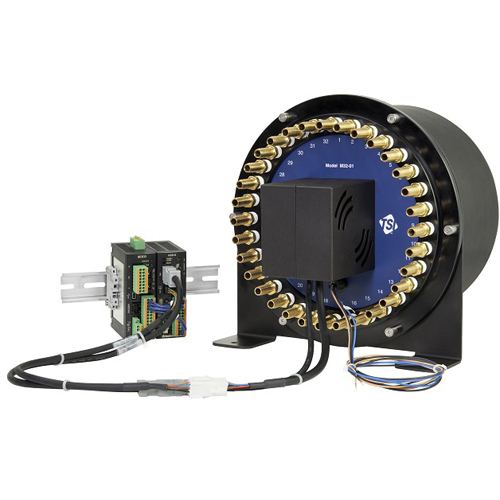

M32-01 Aerosol Sampling Manifold

Accuracy : 1.0 %

Usage : Industrial

Control Mode : Automatic

Power Supply : Electric

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese