Call: 07971550436

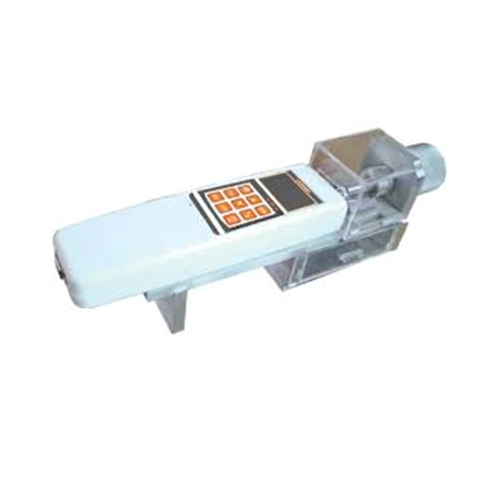

TEST-401 Hardness Tester

TEST-401 Hardness Tester Specification

- Humidity

- 85% RH

- Interface Type

- RS232

- Application

- Rubber and Plastic Hardness Testing

- Features

- Automatic Measurement, Digital Display, Compact Design

- Specimen Size

- Thickness 6 mm, Diameter 35 mm

- Automation Grade

- Semi-Automatic

- Accuracy

- 1 Shore A

- Max Height

- 150 mm

- Test Range

- 10~90 Shore A

- Response Time

- <1 second

- Hardness

- Shore A Scale, 10~90 Shore A

- Equipment Type

- Digital Hardness Tester

- Number of Specimens

- 1

- Operating Voltage

- AC 220V 10%

- Temperature

- 5C ~ 40C

- Frequency

- 50Hz

- Mounting Type

- Benchtop

- Gas Pressure

- 0.6~0.8 MPa

- Resolution

- 0.1 Shore A

- Display Type

- Digital LCD

- Measuring Range

- 10~90 Shore A

- Power Supply

- AC 220V 10%, 50Hz

- Port Size

- 1/8 BSP

- Usage

- Laboratory / Industrial

- Capacity

- Single Specimen Evaluation

- Machine Weight

- 35 Kg

- Test Speed

- 10 mm/min

- Test Width

- 85 mm

- Test Stroke

- 60 mm

- Control Mode

- Digital

- Material Compatibility

- Rubber, Plastics, Elastomers

- Language Support

- English

- Calibration

- Standard calibration block supplied

- Testing Principle

- Indentation hardness by calibrated pressure

- Display Resolution

- 0.1 unit

- Environmental Compliance

- RoHS

- Test Method

- Push Button Automated Test

- Protection Class

- IP20

- Data Output

- USB / RS232

- Sampling Interval

- Adjustable

- Instrument Dimension

- 350 x 270 x 500 mm

About TEST-401 Hardness Tester

Product Features: USP PHARMACOPEIA AND EP COMPLIANT: Compliant with USP < 1217> and EP <2.9.8>.

MULTI-PARAMETER MEASUREMENTS: The TabTest 401 measures:

- Weight

- Width

- Thickness

- Diameter

- Hardness (5 Parameters)

- LCD DISPLAY: Large, bright LCD interface allows detailed method programming without the need for PC software. User-friendly input keys and menus.

- SMALL FOOTPRINT: Ideal for laboratories with limited bench space. The compact, lightweight design is well-suited for portability and use in production settings.

- "OPTIONAL" BUILT-IN PRINTER: Available with an optional 40-column dot matrix built-in printer.

- SAMPLE THROUGHPUT: Approximately 6-10 samples per minute.

- "ADJUSTMENT FREE" TESTING JAWS: No adjustments required. The test jaws are designed to suit all tablet shapes and sizes with a unique grooved design for proper alignment before testing.

- OVER RANGE ALERT: An alert will display if the tablet or sample exceeds the defined hardness range, with the option to continue or abort the test

Accurate and Efficient Hardness Testing

The TEST-401 Hardness Tester utilizes an indentation principle with calibrated pressure to consistently measure the hardness of rubber, plastics, and elastomers. Its automated push button control ensures uniform testing conditions. The digital display delivers immediate and accurate results, making it indispensable for both industrial quality control and laboratory analysis.

User-Friendly Digital Control and Data Management

Equipped with a digital interface and automated features, the TEST-401 offers straightforward operation. The adjustable sampling interval allows for flexible testing protocols, while the USB/RS232 connectivity provides seamless data transfer to computers. Its compact, robust design ensures resilience and ease of use in various operational settings.

FAQ's of TEST-401 Hardness Tester:

Q: How does the TEST-401 Hardness Tester operate?

A: The tester operates using the indentation hardness principle, where a calibrated force is applied to a specimen via a push button automated mechanism. Hardness value is determined based on the material's resistance to indentation, with results shown instantly on the digital LCD display.Q: What materials can be tested with this instrument?

A: The TEST-401 is suitable for testing rubber, plastics, and elastomers. It covers a Shore A hardness range of 10 to 90, ensuring reliable measurements for a variety of flexible and semi-flexible materials.Q: When should standard calibration be performed?

A: Calibration should be carried out regularly or whenever accuracy verification is required, using the supplied standard calibration block to ensure the highest precision in each test.Q: Where can this hardness tester be used?

A: With its benchtop design and robust construction, the TEST-401 is ideal for laboratory and industrial applications, particularly in quality assurance, research, and production environments.Q: What is the process for conducting a hardness test?

A: Prepare a specimen with at least 6 mm thickness and 35 mm diameter, place it in the tester, and initiate measurement via the push button. The instrument automatically executes the indentation and displays the result on the digital LCD within one second.Q: What are the benefits of using the TEST-401 Hardness Tester?

A: This tester provides fast and dependable hardness measurements, minimizes operator error through automated testing, and facilitates data management with digital output. Its compliance with RoHS standards and user-centric features deliver efficient and safe operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hardness Tester Category

TEST-101 Hardness Tester

Accuracy : 1 HA

Usage : Industrial and laboratory

Specimen Size : 6 mm to 50 mm thickness

Automation Grade : Manual

Test Stroke : 35 mm

Max Height : 110 mm

TEST-301 Hardness Tester

Accuracy : 1 Shore A

Usage : Material Hardness Testing

Specimen Size : 6 mm to 10 mm thickness

Automation Grade : Manual

Test Stroke : Up to 100 mm

Max Height : 200 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese