Call: 07971550436

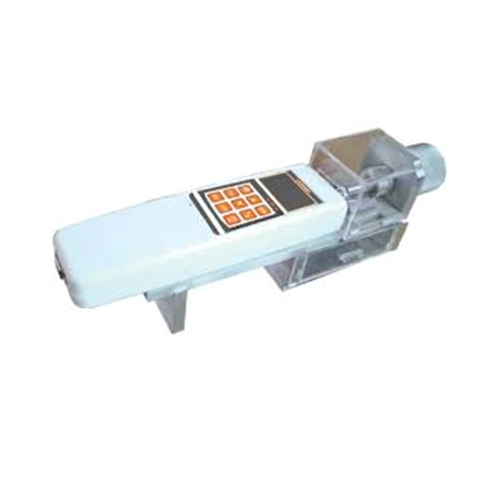

TEST-101 Hardness Tester

TEST-101 Hardness Tester Specification

- Mounting Type

- Tabletop

- Application

- Rubber, plastic, soft materials hardness testing

- Response Time

- Instant

- Frequency

- 50 Hz

- Automation Grade

- Manual

- Port Size

- 6 mm

- Features

- Portable, compact, high precision

- Interface Type

- RS232

- Test Range

- 0-100 HA

- Max Height

- 110 mm

- Humidity

- 30%-80%RH

- Number of Specimens

- 1

- Temperature

- 10-35C

- Specimen Size

- 6 mm to 50 mm thickness

- Accuracy

- 1 HA

- Resolution

- 0.1 HA

- Display Type

- Digital LCD

- Measuring Range

- 0-100 HA

- Gas Pressure

- 0.5-0.7 MPa

- Operating Voltage

- 220V AC

- Hardness

- Shore A

- Power Supply

- AC 220V 50Hz

- Equipment Type

- Bench-top

- Usage

- Industrial and laboratory

- Capacity

- <1000 N

- Machine Weight

- 28 kg

- Test Speed

- 150 mm/min

- Test Width

- 64 mm

- Test Stroke

- 35 mm

- Control Mode

- Manual

- Calibration

- Manual and automatic options

- Data Storage

- Up to 250 test results

- Accessories Supplied

- Carrying case, Calibration block, User manual

- Repeatability

- <0.5%

- Test Method

- Indentation depth measurement

- Compliance Standard

- ISO 868

- Safety Protection

- Overload protection

- Operating Environment

- Indoor, dust-free area

- Indenter Type

- Steel rod

- Power Consumption

- 20 W

About TEST-101 Hardness Tester

Key Features

- Real-Time Data Transfer

- Instantly send test results to your PC via RS-232 interface. Monitor real-time graphs and data using compatible software for streamlined analysis.

- Multi-Unit Measurement

- Easily switch between Newton (N), Kilogram Force (Kgf), and Pound Force (lbf) with automatic unit conversion.

- Accurate Hardness Measurement

- Designed to precisely measure the hardness of tablets, with a range of 5500N and accuracy of 0.05% FS.

- Upper/Lower Limit Alerts

- Set tolerance levels and receive alerts through visual (red/green LED indicators) and audio (buzzer) signals when measurements fall outside the defined limits.

- User-Friendly Interface

- Operate effortlessly with a 2.8-inch touch screen display and intuitive 9-key interface.

- Data Storage & Average Calculation

- Store up to 10 test results and automatically calculate the average hardness value for consistent quality assurance.

Specifications

| Parameter | Details |

|---|---|

| Display | 2.8 inch Touch Screen |

| Operation | 9-Key User-Friendly Keypad |

| Hardness Range | 5 500 N |

| Accuracy | 0.05% FS |

| Units | N, Kgf, lbf (Auto Conversion) |

| Interface | RS-232 Port |

| Battery | 1200 mAh, 8.4V Rechargeable |

| Peak Force Measurement | Yes |

| Safety Cover | Acrylic Safety Glass |

| Stored Results | Up to 10 (with Average Calculation) |

| Calibration | Zero Point Adjustment Available |

| Programmable Tolerances | Yes (T1, T2) |

| Tablet Size Compatibility | 2mm 28mm |

| Dimensions | 355(L) 60(B) 105(H) mm |

| Weight | 2 Kg |

| Power Supply | 230V, 50Hz AC to 12V DC, 300mA Adapter |

High Precision Hardness Testing

The TEST-101 delivers highly accurate measurements for rubber, plastic, and other soft materials. Its steel rod indenter and indentation depth method ensure reliable, repeatable results with less than 0.5% repeatability error, conforming to ISO 868 standards. This makes it indispensable for quality assurance in industrial and laboratory environments.

User-Friendly Operation and Versatility

Designed for convenience, the tester features both manual and automatic calibration, a digital LCD screen, and intuitive controls. Its compact, portable build is suitable for tabletop use, and data storage capability allows you to record up to 250 results for traceability. The included accessories, like the carrying case and calibration block, enhance usability.

Safe and Robust Design

With overload protection and a sturdy 28 kg bench-top configuration, the TEST-101 prioritizes operator safety. It operates efficiently in controlled, dust-free indoor settings, handling specimen thicknesses from 6 mm up to 50 mm. Its robust construction ensures long-term reliability, making it a valuable asset for manufacturers, laboratories, and quality control teams.

FAQs of TEST-101 Hardness Tester:

Q: How does the TEST-101 measure material hardness?

A: The TEST-101 utilizes an indentation depth measurement method, employing a steel rod indenter to determine Shore A hardness values. It accurately records the depth of indentation under a specified force, suitable for assessing rubber, plastic, and other soft materials.Q: What types of materials can the TEST-101 test?

A: The device is engineered for testing the hardness of rubber, plastics, and various soft materials that conform to the Shore A scale, making it suitable for industrial and laboratory applications involving flexible specimens.Q: When should I calibrate the TEST-101 Hardness Tester?

A: Calibration should be performed regularly to ensure measurement accuracy, especially after extended use or when switching materials. The tester offers both manual and automatic calibration methods, and a calibration block is supplied for this purpose.Q: Where can I use the TEST-101 Hardness Tester?

A: The tester is designed for indoor, dust-free environments such as laboratories and industrial quality control areas, within an operating temperature of 10-35C and humidity range of 30%-80%RH.Q: What is the process for conducting a hardness test with this equipment?

A: Secure your specimen (6 to 50 mm thick) on the device, select the appropriate control mode, and initiate the test using the manual controls. The tester measures indentation depth at a speed of 150 mm/min, displays the result instantly on the digital LCD, and can store up to 250 entries.Q: How does the device ensure operator safety during operation?

A: The TEST-101 is equipped with overload protection, safeguarding both the operator and the device during high-force applications, and is designed for stable and secure tabletop use.Q: What are the key benefits of using the TEST-101 Hardness Tester?

A: Key benefits include high measurement precision, robust data storage, compliance with ISO 868 standards, user-friendly manual or automatic calibration, and suitability for a wide range of industrial and laboratory testing tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hardness Tester Category

TEST-401 Hardness Tester

Port Size : 1/8 BSP

Features : Automatic Measurement, Digital Display, Compact Design

Automation Grade : SemiAutomatic

Response Time : <1 second

Frequency : 50Hz

Application : Rubber and Plastic Hardness Testing

TEST-301 Hardness Tester

Port Size : Standard

Features : Lightweight, Portable, Robust Construction

Automation Grade : Manual

Response Time : Instant

Frequency : 50 Hz

Application : Rubber, Plastic, Flooring, and Elastomers

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese